Gas leaks are among the most dangerous yet often invisible hazards in homes, factories, and industrial environments. Whether it involves natural gas, propane, or other combustible gases, even a small leak can lead to fire, explosion, or health risks if not detected promptly. This is where a gas leak detector becomes essential. Understanding how a gas leak detector works, its types, components, and maintenance requirements can help you ensure safety and prevent accidents before they occur.

This complete guide explains everything you need to know about how a gas leak detector operates, what technologies are behind it, and how to use one effectively in both residential and industrial applications.

1. What Is a Gas Leak Detector?

A gas leak detector is an electronic device designed to identify the presence of harmful gases in the air. It can sense gases such as methane, carbon monoxide, propane, butane, hydrogen sulfide, or other toxic and combustible gases. Once a specific gas concentration exceeds a set threshold, the detector triggers an alarm to alert occupants or operators to take action.

Gas leak detectors can be portable or fixed. Portable devices are handheld tools commonly used by technicians to check pipelines, appliances, or confined spaces. Fixed detectors, on the other hand, are installed permanently in strategic locations to continuously monitor air quality and provide early warnings.

2. Why Gas Leak Detection Is Important

Detecting gas leaks is crucial for several reasons:

Safety: Gas leaks can lead to fires or explosions. Early detection helps prevent accidents.

Health: Inhaling gases like carbon monoxide or hydrogen sulfide can cause poisoning or even death.

Environmental Protection: Some gases contribute to greenhouse emissions and air pollution.

Operational Efficiency: Industrial systems rely on accurate gas detection to maintain safe operating conditions.

A gas leak detector acts as the first line of defense, alerting users before a dangerous situation escalates. Without it, gas leaks might go unnoticed until it’s too late.

3. How a Gas Leak Detector Works

Understanding the working principle of a gas leak detector requires looking at its core components and sensor technology. These devices rely on physical and chemical reactions between the target gas and the detector’s sensor material to identify gas presence and concentration.

3.1. The Sensing Element

The heart of every gas leak detector is its sensor. Different detectors use different sensing principles depending on the type of gas being monitored. Common sensor types include:

Catalytic Bead Sensors:

These sensors detect combustible gases by oxidation. When gas molecules contact the heated sensor element, they burn slightly, causing a temperature rise that changes the sensor’s resistance. The detector interprets this change as the gas concentration.Infrared Sensors:

Infrared (IR) sensors work by measuring how gas molecules absorb infrared light at specific wavelengths. Each gas has a unique absorption pattern, allowing the detector to identify and measure it accurately.Electrochemical Sensors:

These are commonly used for toxic gases like carbon monoxide. The sensor contains an electrolyte that reacts chemically when exposed to the target gas, generating an electrical current proportional to gas concentration.Semiconductor Sensors:

Semiconductor detectors use metal oxide materials that change conductivity when gas is present. They’re compact and affordable, often found in consumer-grade gas leak detectors.

3.2. Signal Processing

Once the sensor detects the gas, it converts the reaction into an electrical signal. This signal is processed by the detector’s internal microcontroller, which interprets the strength of the signal and determines whether it exceeds safe limits.

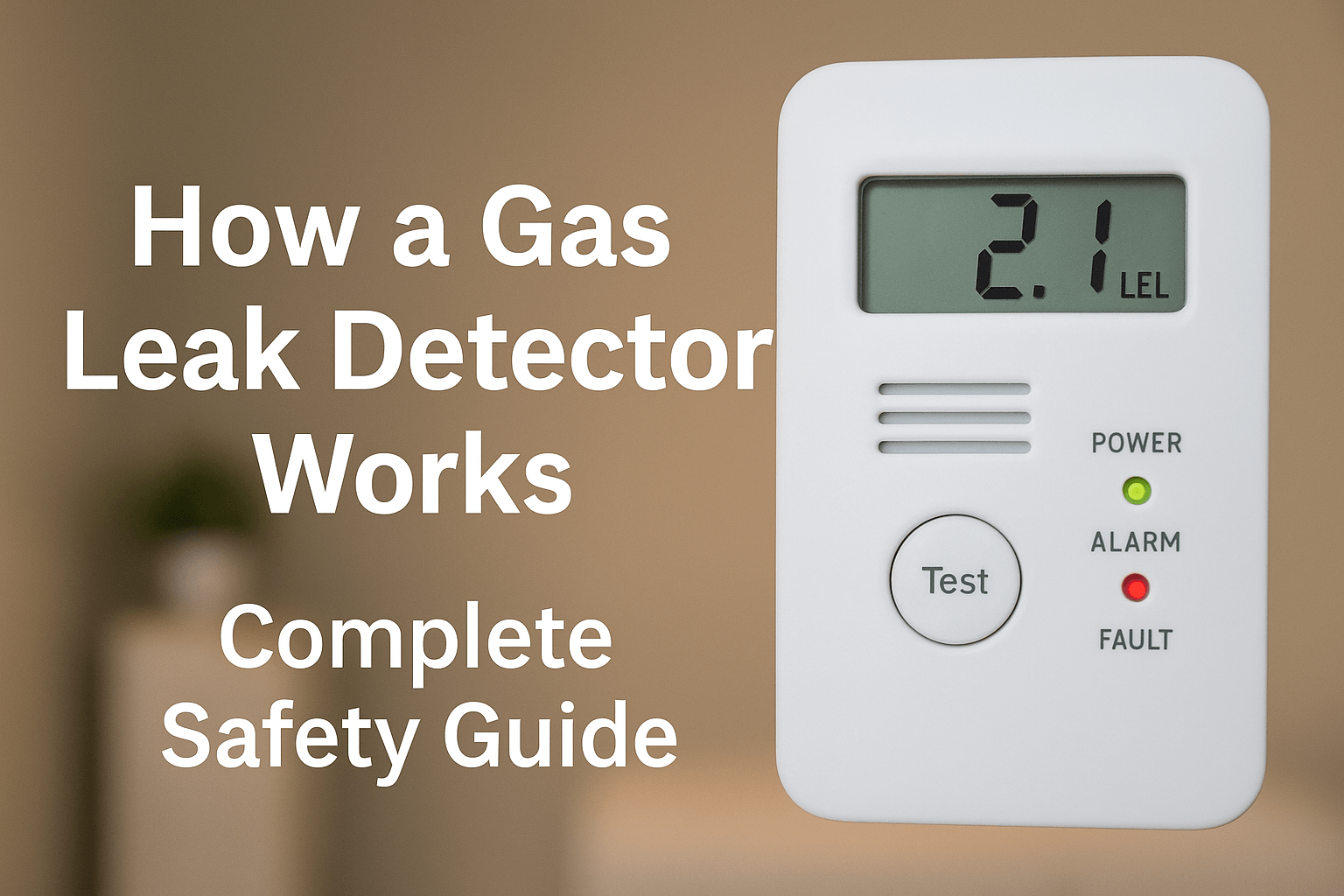

If the concentration level is dangerous, the gas leak detector triggers an alarm — either audible, visual (LED flashing), or through a digital alert in smart systems.

3.3. Alarm and Notification System

A reliable gas leak detector provides multiple forms of alerts to ensure no warning goes unnoticed. These include:

Audible Alarms: Loud beeps or sirens to capture attention immediately.

Visual Alarms: Flashing lights or digital displays showing gas levels.

Remote Alerts: Smart detectors can send push notifications or messages to mobile devices, ensuring users get alerts even when away from the site.

4. Types of Gas Leak Detectors

There are several categories of gas leak detectors, each suited to specific environments and gases. Here’s an overview:

4.1. Fixed Gas Leak Detectors

Installed permanently in homes, factories, or refineries, these continuously monitor the environment. They are ideal for detecting ongoing or recurring leaks in high-risk zones such as kitchens, storage rooms, or processing units.

4.2. Portable Gas Leak Detectors

Compact and battery-powered, these are used by engineers, inspectors, and maintenance personnel. They help locate precise leak sources during inspections or emergency responses.

4.3. Smart Gas Leak Detectors

These modern detectors connect to Wi-Fi or Bluetooth networks. They can be integrated with home automation systems, allowing real-time monitoring via smartphones or control panels. Some models can even shut off gas valves automatically when a leak is detected.

4.4. Industrial Gas Leak Detectors

Industrial detectors are designed for large-scale or hazardous applications, such as chemical plants, oil refineries, or manufacturing facilities. They may include multi-gas detection capabilities and rugged housings for harsh conditions.

5. Gases Commonly Detected

The effectiveness of a gas leak detector depends on the type of gases it can sense. Some common gases include:

Methane (CH₄): Main component of natural gas; highly flammable.

Propane (C₃H₈): Used in LPG; heavy gas that can accumulate in low areas.

Carbon Monoxide (CO): Odorless and toxic; produced by incomplete combustion.

Hydrogen Sulfide (H₂S): Found in sewers, oil fields; extremely toxic.

Ammonia (NH₃): Used in refrigeration; irritant and corrosive.

Hydrogen (H₂): Used in industrial processes; highly flammable.

Each detector type is calibrated to detect specific gases accurately, ensuring reliable performance in its designated setting.

6. Applications of Gas Leak Detectors

The use of a gas leak detector spans multiple industries and domestic applications:

6.1. Residential Use

In homes, detectors are commonly installed in kitchens, basements, or near gas appliances such as stoves, heaters, or boilers. They prevent accidental poisoning or explosions due to unnoticed leaks.

6.2. Industrial Use

Factories, refineries, and chemical plants rely on detectors to protect workers and equipment. Continuous gas monitoring systems ensure compliance with safety standards.

6.3. Commercial Use

Restaurants, hotels, and commercial kitchens install detectors to safeguard staff and customers. Similarly, laboratories and hospitals use detectors to monitor gas cylinders or equipment.

6.4. Automotive Use

Some vehicles, particularly those using LPG or CNG, include built-in gas detection systems to prevent onboard leaks.

7. How to Install a Gas Leak Detector

Installation plays a crucial role in ensuring accurate readings. Incorrect placement can result in false alarms or missed leaks.

7.1. Placement Tips

For lighter gases like methane or hydrogen, install the detector near the ceiling.

For heavier gases like propane or butane, mount it closer to the floor.

Keep detectors at least 1–3 meters away from gas appliances to avoid interference.

Avoid installing near ventilation ducts or windows, as airflow may disperse gases.

7.2. Power and Connectivity

Many fixed detectors require direct wiring or plug-in power, while portable versions rely on batteries. Smart versions may need Wi-Fi or app setup.

8. Calibration and Maintenance

To maintain accuracy, a gas leak detector must be calibrated regularly. Over time, sensor sensitivity can drift due to environmental exposure or natural wear.

8.1. Calibration Process

Calibration involves exposing the detector to a known concentration of gas and adjusting the output accordingly. This ensures the device provides correct readings.

8.2. Maintenance Tips

Check sensor function at least once a month.

Replace batteries or power sources as required.

Keep sensors clean and free from dust or oil.

Follow manufacturer recommendations for replacement intervals.

Proper maintenance extends the lifespan of the device and guarantees reliability in emergencies.

9. Common Problems and Troubleshooting

Even high-quality detectors can face occasional issues. Knowing how to handle them is vital:

Problem Possible Cause Solution False alarms Sensor contamination, temperature fluctuations Clean or recalibrate the sensor No alarm despite leak Faulty sensor or battery Replace sensor or power supply Weak signal Interference from nearby devices Relocate or shield the detector Continuous beeping End-of-life or sensor malfunction Replace the detector 10. Choosing the Right Gas Leak Detector

Before buying, consider the following factors:

Gas Type: Make sure the detector is designed for the specific gas you want to monitor.

Detection Range: Check the sensitivity and range to ensure it meets your needs.

Power Source: Choose between battery-operated, plug-in, or hardwired systems.

Alarm System: Opt for models with both visual and audible alerts.

Certification: Look for certified devices that meet international safety standards (e.g., UL, CE).

Ease of Use: User-friendly interfaces and clear displays make operation simpler.

Selecting the correct gas leak detector based on your environment ensures accurate and dependable safety monitoring.

11. Future of Gas Leak Detection

The next generation of detectors is becoming smarter and more connected. Integration with the Internet of Things (IoT) allows detectors to communicate directly with smartphones, control panels, or even fire suppression systems. Artificial intelligence is also being incorporated to improve accuracy, reduce false alarms, and predict leak risks based on historical data.

Additionally, advanced sensors with longer lifespans and self-calibration features are emerging, reducing maintenance costs and improving overall safety reliability.

12. Safety Tips When Using a Gas Leak Detector

Test your detector monthly to confirm it’s functioning correctly.

Never ignore a warning alarm — always verify the source of the leak immediately.

Use portable detectors for confined spaces or before entering potentially hazardous areas.

Keep the device dry and avoid exposure to corrosive chemicals.

Replace outdated detectors promptly, as sensors lose efficiency over time.

A gas leak detector is a preventive tool, but it only works effectively when installed and maintained properly.

13. Conclusion

A gas leak detector is one of the most essential safety devices for any environment where gases are used or stored. By continuously monitoring for the presence of hazardous gases and providing early warnings, it helps prevent fires, explosions, and health hazards.

Understanding how a gas leak detector works—from sensing mechanisms to alarm systems—empowers you to choose the right model and use it effectively. Regular maintenance, correct installation, and periodic calibration ensure accurate performance when it matters most.

In homes, businesses, or industrial plants, adopting reliable gas detection technology is not just a precaution—it’s a responsibility that protects lives, property, and the environment.

Frequently Asked Questions (FAQ)

1. What does a gas leak detector actually detect?

A gas leak detector identifies the presence of combustible or toxic gases such as methane, propane, carbon monoxide, or hydrogen sulfide. It measures gas concentration in the air and triggers an alarm if the level becomes unsafe.

2. How accurate are gas leak detectors?

The accuracy of a gas leak detector depends on the sensor type, calibration, and environmental conditions. High-quality detectors can detect even minute gas concentrations, while low-end models may require more frequent calibration to stay reliable.

3. Where should I install a gas leak detector in my home?

For lighter gases like methane or natural gas, install the detector near the ceiling. For heavier gases such as propane or butane, place it near the floor. Always position it close to gas appliances but not directly above them to avoid false alarms.

4. How often should I test my gas leak detector?

You should test your gas leak detector at least once a month to ensure it’s functioning properly. Regular testing helps identify weak batteries, faulty sensors, or calibration issues before an emergency occurs.

5. Can a gas leak detector detect carbon monoxide (CO)?

Only if it’s specifically designed for that purpose. Some models are multi-gas detectors capable of sensing carbon monoxide, while others are made solely for combustible gases. Always check the product specifications before purchase.

6. Do I need more than one gas leak detector in my home?

Yes, if you have multiple areas where gas is used—such as the kitchen, basement, or near a water heater—it’s best to install several detectors. This ensures full coverage and faster leak detection throughout the home.

7. How long does a gas leak detector last?

Most detectors last between 3 to 5 years, depending on sensor quality and usage conditions. Always follow the manufacturer’s guidelines for sensor replacement and calibration intervals to maintain accuracy.

8. What should I do if my gas leak detector alarms?

If the alarm sounds, turn off your gas supply immediately (if safe to do so), open windows for ventilation, and leave the area. Avoid using electrical switches or flames. Contact your gas supplier or emergency services to inspect and repair the leak.

9. Are there smart gas leak detectors?

Yes. Modern detectors can connect to smartphones or smart home systems through Wi-Fi or Bluetooth. They send real-time alerts, track gas levels, and even shut off valves automatically in some advanced models.

10. Can I use a gas leak detector outdoors?

Some industrial and rugged models are weatherproof and suitable for outdoor environments, but most household detectors are designed for indoor use only. Always check whether the detector is rated for outdoor applications before installation.